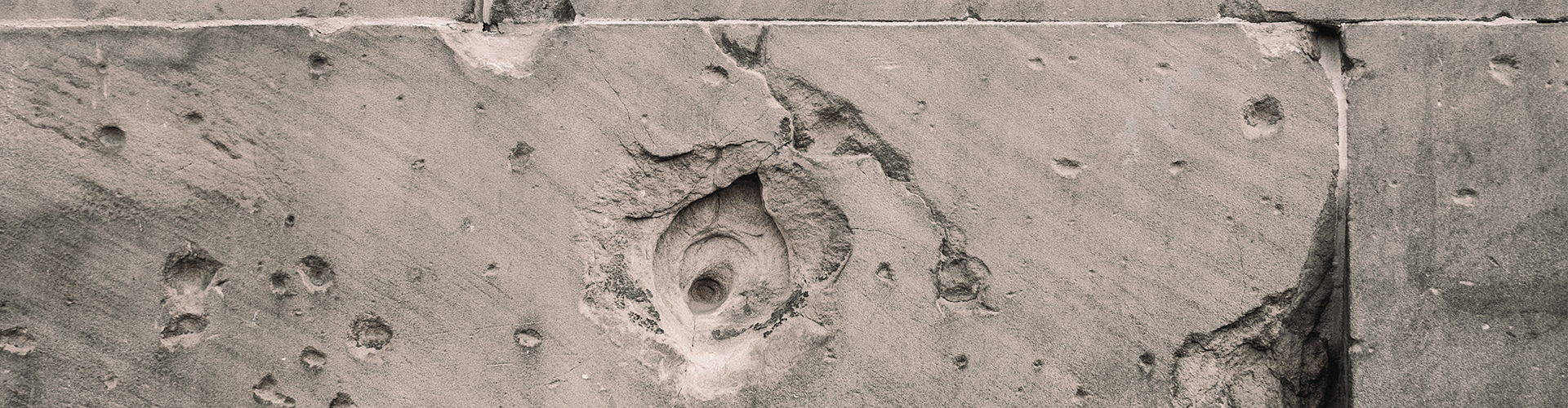

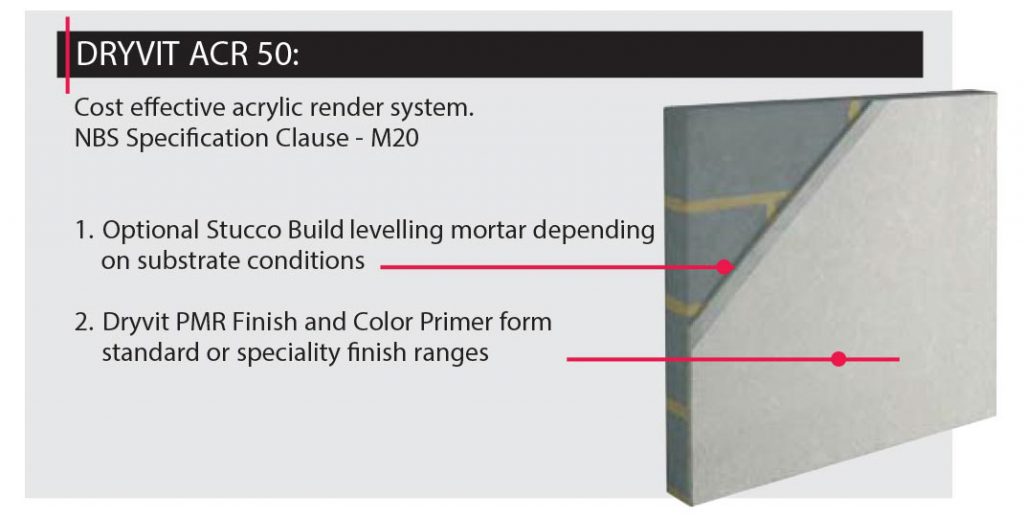

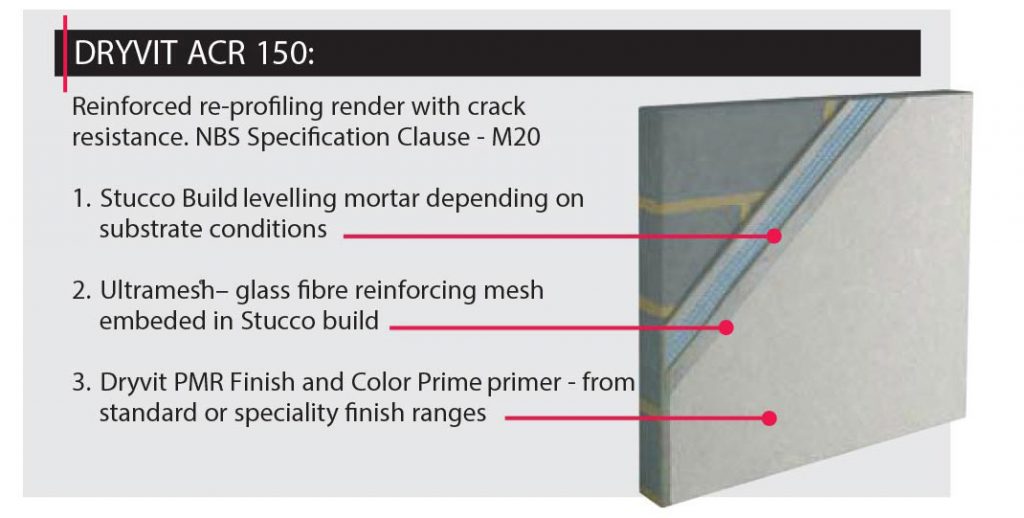

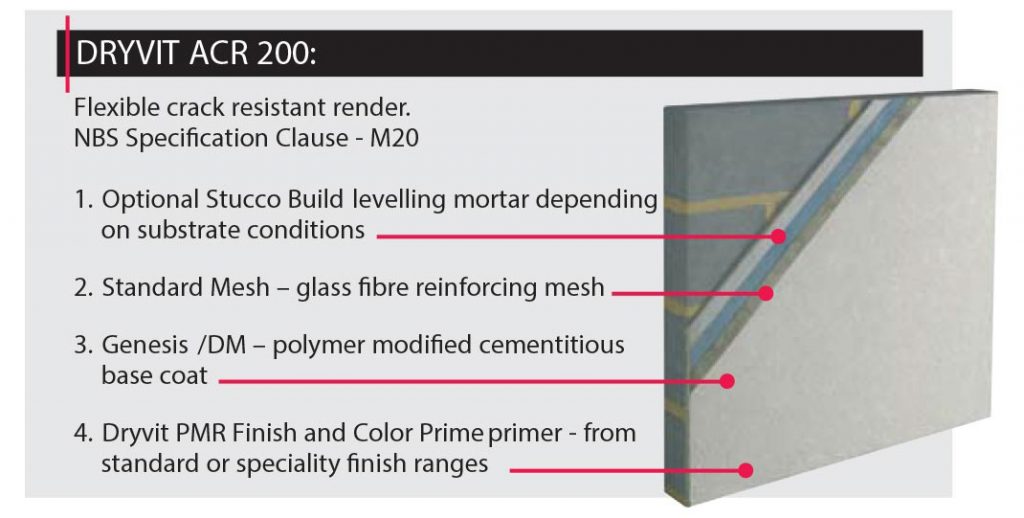

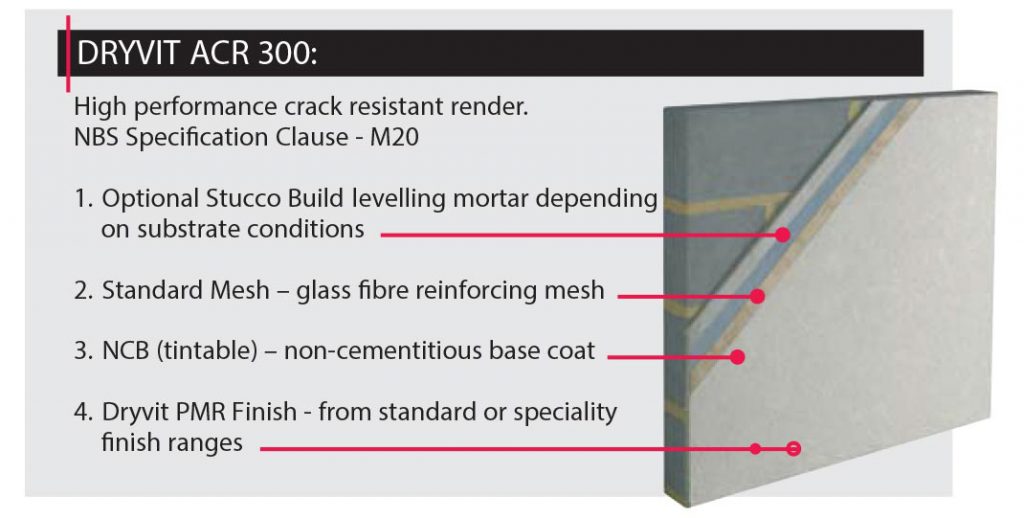

Dryvit ACR systems and the Cement Board MD Finish System are a range of 100% acrylic polymer based anti-crack renders designed to out perform the shrinkage and cracking characteristics of traditional renders. The range offers a variety of coloured and textured coating options providing various levels of protection when used in the different component combinations.

Dryvit ACR systems are generally installed over a Dryvit polymer modified re-profiling mortar where levelling is required, on to exterior concrete, brickwork, blockwork, plastered or painted surfaces in new build or refurbishment projects.

The Cement Board MD Finish System incorporates an exterior grade cement board fixed to vertical batons and is ideal where a cavity system is called for without the need for exterior insulation. Commonly applied over timber or steel framed substrates incorporating an approved sheathing and breather membrane in new build residential and low-rise commercial projects.

Application of the systems are carried out by Specialist Installers employing operatives who have been trained in the use of Dryvit materials. In addition Dryvit are committed to providing on site support to their network of Specialist Installers when called upon. Details of recommended Specialist Installers are available from Dryvit UK Ltd.

Standard details are available for both Dryvit ACR systems and the Cement Board MD Finish System and can be downloaded from www.dryvit.co.uk. Dryvit offers a CAD service to produce bespoke details in line with specific project needs

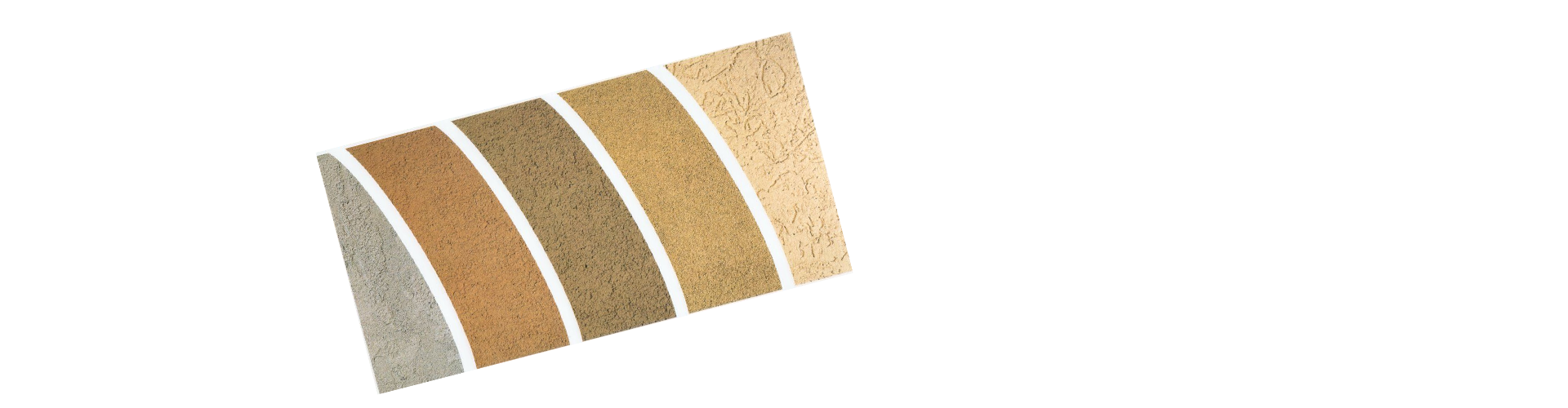

Dryvit 100% acrylic finishes contain quartz aggregates of various sizes and use Dirt Pickup Resistant (DPR) and Proven Mildew Resistance (PMRTM) chemistry, ensuring the highest standard of fade resistance and ensuring low maintenance. The standard finish range is available in five different textures with over 360 chart colours to select from. If your desired colour is not available from our standard finish range then we have a colour matching service that will be sure to satisfy your requirements. Even the look of natural stone, granite and brick is possible from our range of speciality finishes.

• Crack resistance. Location and frequency of movement joints is greatly reduced or even eliminated compared with that of traditional renders due to the high performance crack resistance of our systems.

• Weatherability. Dryvit systems are formulated to provide the utmost in weather protection providing a resilient barrier against wind and water.

• Durability. The combination of system components provide unsurpassed long-term durability meeting design requirements for use in virtually any location.

• Aesthetics. Dryvit finishes are available in a wide array of textures in both standard and custom colours. Our speciality finishes enable designers to replicate a variety of real stone or brick finishes from limestone to granite at a fraction of the cost.

• Testing. Independently certified by BBA and other international test bodies. Dryvit manufacturing plants are ISO 9001:2000 certified, demonstrating the highest standards of quality and consistency.